The world is increasingly moving towards renewable energy and solar PV plants are the first choice of industries to generate green power. While a solar PV plant can be easily synchronised with the grid, industries have other energy sources too which call for careful integration to achieve optimal solution.

Industrial process plants have requirements in terms of fluctuating load, reliability of power, steam consumption etc. which need to be managed seamlessly. When introducing renewable energy as a source of power, it is critical to design a solution that fulfils all the process requirements from multiple energy sources and at the same time maximises the use of solar power.

The case study below is a testimony of our engineering prowess where we helped integrate solar PV plant with the grid, multiple diesel generators and a steam turbine so as to maximise the utilisation of solar power and meet plant requirement under multiple operating scenarios.

The Requirement:

The customer receives power supply from the national grid for a connected load of 2500 kVA. A 650 kW back pressure turbine (BPT) was installed and in case of unavailability of the grid, the customer is using a DG set of 1200 kW to support the load and provide reference to the BPT. All the resources are currently monitored by a controller.

The customer wanted to install a 1000 kWp solar photovoltaic (PV) plant to reduce their electricity bill and carbon footprint.

The requirement was to manage the resources in sequential preference as mentioned under different scenarios.

Scenario1 – Grid is available, the following sequences of the electricity sources are to be maintained:

- BPT – as a part of the existing process

- Solar PV

- Grid

Scenario 2 – Grid is off / unavailable, DG to provide the reference signal to BPT and solar PV. In this case, following sequences of sources should be maintained:

- BPT – as a part of the existing process

- Solar PV

- DG

The Goal:

The power output of a solar PV system varies depending on the irradiance and temperature at a particular time. The team undertook the below steps for achieving the goal:

- Maximise power from the solar PV plant

- Minimise power from diesel generator (DG) – the costliest power source

- Avoid reverse power flow from solar PV to DG, to avoid damage to DG windings

- Maintain system stability in absence of the grid

The Solution:

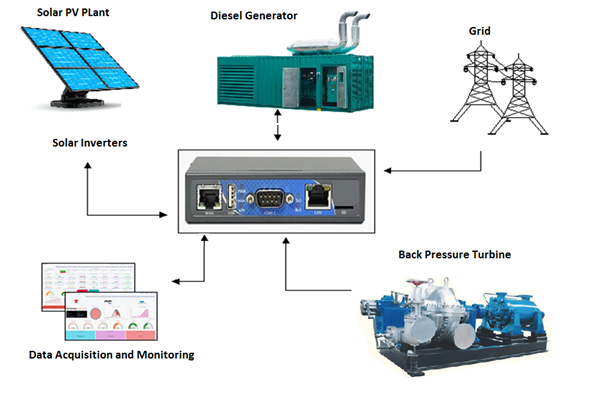

The Thermax team devised a solution using IoT controllers with smart algorithms and logic for dynamic ramp up / ramp down of solar inverters.

The IoT controller is the central component of the solution for hybrid systems consisting of solar PV and other resources along with the DG. It has the flexibility to write an application programme to ensure a demand-oriented control of the PV system that is a factor of the plant’s load and other resources’ characteristics. Thus the DG operates in a reliable and stable state even with high levels of PV power.

It is achieved through power sensing, power flow and measurement at various points in the client electrical network as per the below schematic.