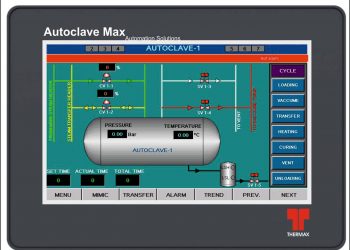

Thermax offered process automation for the Aerated Autoclaved Concrete (AAC) industry consists of control valves, bellow seal isolation valves, pressure transmitters, temperature transmitters and condensate removal system which operate on PLC control.

SPECIALITY PRODUCTS

Thermax offers speciality products which give more benefits to the customer like increase in boiler efficiency, reduction in fuel consumption, monetary savings, etc. Our product 'High Pressure Condensate Recovery System (HPCRS)' received the CII National Award for Excellence in Energy Management in 2018.

The complete process involves vacuuming, heating, curing (holding), transfer and venting cycles. It requires precise control of vacuum time, heating temperature gradient, curing cycle time, steam transfer and venting process. Condensate removal from autoclave is very important as it is contaminated with cement particles and may lead to choking of the condensate removal system.

The Thermax system consists of control valves, bellow seal isolation valves, pressure transmitters, temperature transmitters and condensate removal system which operate on PLC control. With the PLC system, the customer can monitor and maintain required process parameters. The system also provides output in the form of graphs and charts for various critical parameters to control the system effectively.

Since the condensate is contaminated with cement particles, condensate recovery back to boiler feed water tank is not recommended. Instead, the condensate heat for heating fresh makeup water should be recovered in a heat exchanger.

Product Features

- Process cycles such as vacuuming, heating, curing (holding), transfer and venting are

precisely controlled by PLC. - Graphical trends for critical control parameters.

- Indirect heat recovery from contaminated condensate.

- Efficient condensate evacuation and recovery for energy conservation.

- Efficient recovery and utilization of flash steam.

System Benefits

- User friendly system with ease of operation

- Precise control of critical pressure and temperature parameters

- Proper utilization of vent steam in another autoclave during the transfer cycles

- Level based condensate removal system to avoid choking of condensate lines

- Condensate and flash steam heat recovery for fresh makeup water heating/slurry preparation

- PLC based automation ensures effective staggering of autoclave operations which improves plant utilization factor.

- Aerated Autoclaved Concrete